-

MIM products usually have the following characteristicsTime of issue : 2020- 03-13

The most suitable wall thickness for MIM is no more than 6mm. Thicker outer wall is acceptable, but the cost will be increased due to the longer processing time and extra material used. In addition, u

-

Rich variety of raw materials, and the variety of domestic powder metallurgy products has been expandedTime of issue : 2017- 09-09

Rich variety of raw materials, and the variety of domestic powder metallurgy products has been expandedTime of issue : 2017- 09-09In terms of raw materials, at present, the main raw materials of powder metallurgy in China are not only reduced iron powder, electrolytic copper powder, etc., and domestic production of atomized iron powder, stainless steel powder, high-speed steel powder, coated powder and various element metal MIM powder, Ceramic powders can basically meet the needs of domestic production of high-strength parts, and can also produce raw material powders for special purposes, which greatly expands the variety of powder metallurgy products, but there is still a large gap in quality and variety from abroad.

-

Development of metal injection moldingTime of issue : 2015- 12-02

Development of metal injection moldingTime of issue : 2015- 12-02Metal injection molding can be traced back to the powder injection molding preparation of ceramic spark plugs that began in the 1920s. In the following decades, powder injection molding mainly focused on ceramic injection molding. It wasn't until 1979 that the metal injection molding products of Parmatech formed by Wiech and others won two awards. At that time, Wiech and Rivers were granted patents. Powder injection molding began to turn to metal injection molding.

-

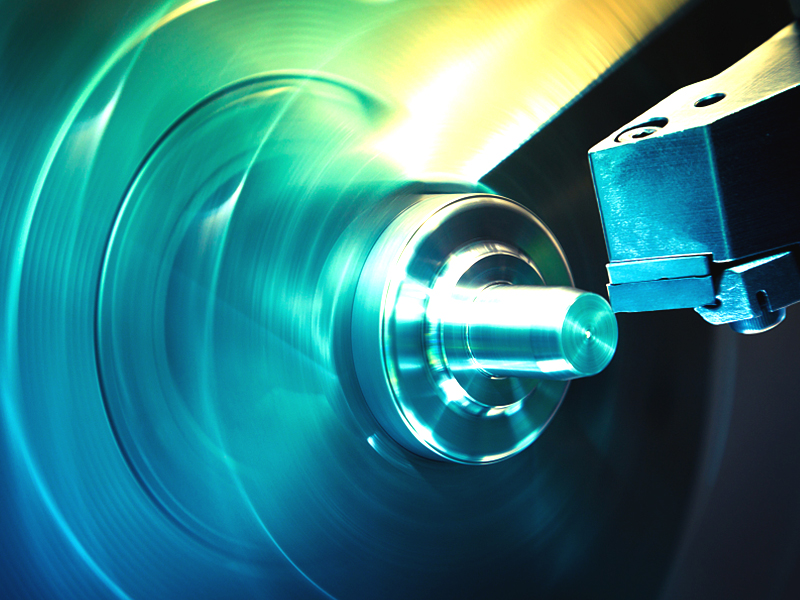

Metal injection molding technology in detailTime of issue : 2018- 06-19

Metal injection molding technology in detailTime of issue : 2018- 06-19Metal injection molding (referred to as MIM) is a technology combining powder metallurgy and injection molding, which breaks through the traditional powder metallurgy product shape and strength limitations, also breaks through the strength limitations of die casting, breaks through the material flow restrictions of stamping molds, and breaks through precision. Mass production restrictions for casting and high cost constraints for turned parts.

-

The market competition pattern of 3D printed metal powder may changeTime of issue : 2018- 06-19

The market competition pattern of 3D printed metal powder may changeTime of issue : 2018- 06-19The market competition pattern of 3D printing metal powder will change as more companies enter or increase their production and R & D efforts in the field of metal powder. In 2016, GKN, Oerlikon and Alcoa made active strategic plans.

cq9电子平台网站.

ADD:9th Floor, Zhongan Construction Building, Sucity New District, Suqian City, China.

TEL:0527-84391028

Mobile:166 9228 3153

FAX:0527-7823172

E-mail:sqrddb@163.com

CopyRight © 2015 cq9电子平台网站. 苏ICP备19042914号-1